PRODUCT

Clean Room Air Shower Single Person for Pharmaceutical Industry

Product Attributes :

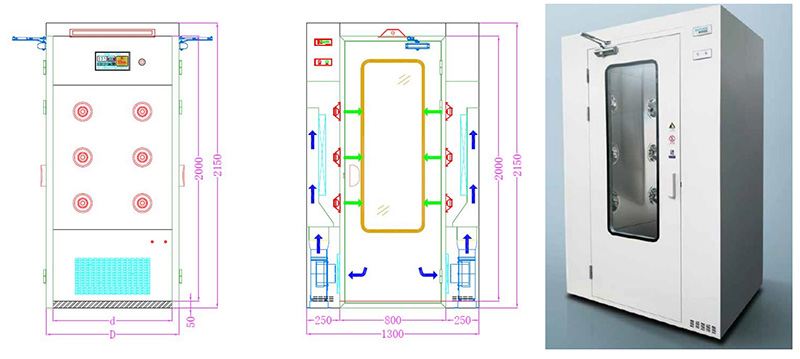

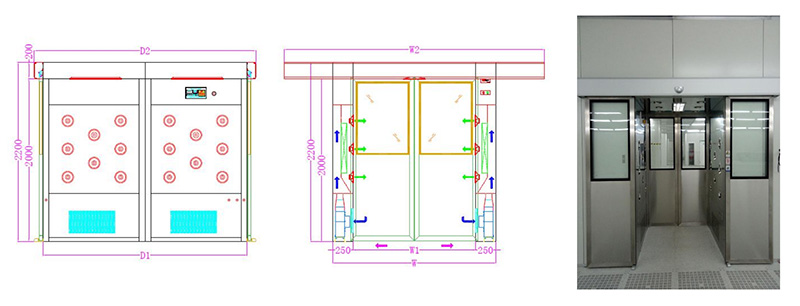

1.Air shower clean room Fully auto controlled by computer, 2 mechanical interlocking door, automatically blow and shower.

2. Duration for showering can be adjusted from 0 to 99 seconds with time display and voice prompt. It is easy to operate with membrane touch switches.

3. Floor and nozzles are made of quality stainless steel.

4. 99.99%@0.3μm, Efficiency can reach 99.99%@0.3μm with Pre filter and Hepa filter.

5. Air velocity can up to 25m/s. professional and fast design, non-standard products.

Product Description

Air showers play a critical role in maintaining cleanroom integrity by removing loose contaminating particles from people and products before they enter the room.

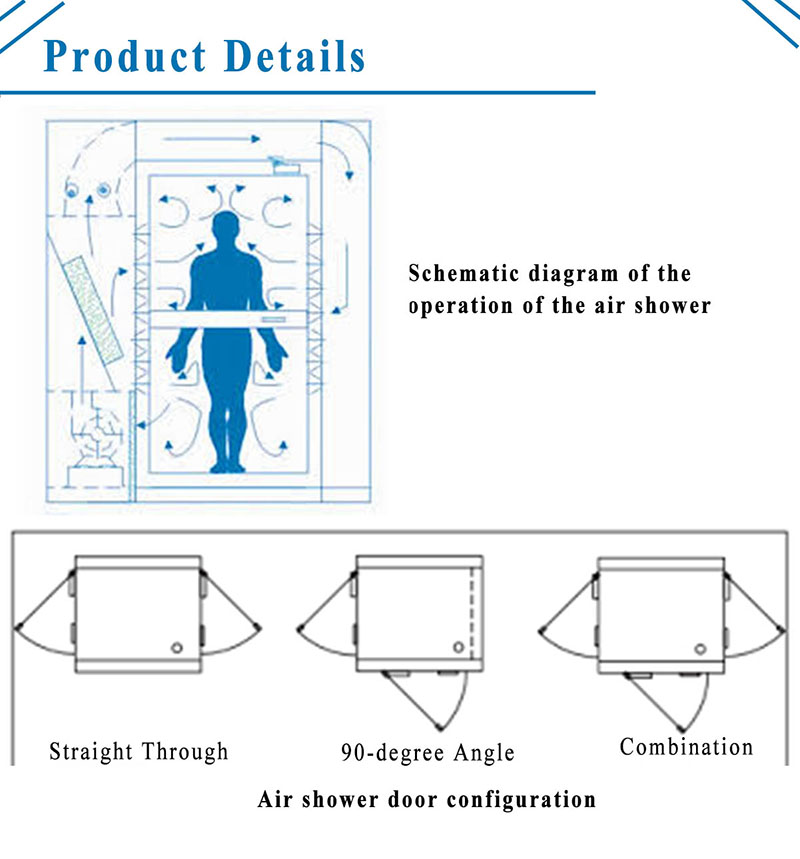

Cleanroom air showers function as an entry system. The cleanroom entry system allows for the proper class identification and procedures for dressing and storing garments. At a minimum, the isolated air shower contains a blower and motor, HEPA/ULPA filtration, a recirculating exhaust system, and interlocking doors. However, the design could incorporate additional features, functions, and benefits, depending on the intended use.

The primary features of a properly designed air shower include:

- Cycle time: The most crucial determinant of the shower's effectiveness is the time it takes to remove contamination completely.

- Dwell time: Dwell time is the period between the end of the cycle and opening door. It ensures that the removed contaminants settle at the end of the process to prevent them from being swept into the cleanroom when the doors open.

- Filtration: Filtration is critical to remove particulates from the cleanroom apparel and extract them from the environment before allowing the worker to enter the cleanroom.

- Protocol: Proper protocol ensures maximum efficacy of the air shower. Best practices, such as placing hands on the head while rotating 360°, allows for thorough contamination removal.

- Points of impact: Airflow from nozzles distributed across the walls and ceiling hit multiple points of impact. The diffuse contact creates a pulsating effect on the garments that dislodges the particulates.

STANDARD FEATURES:

- High-velocity, high-volume air flow, which allows for fast and efficient decontamination of the atmosphere

- Magnetic interlocks

- LED interior lighting

- Inspection panels for air supply ducts

- Silicone-free urethane sealant

- Stainless steel door frames are available

- Standard-sized HEPA filters and prefilters that have no-leak, negative pressure–reliability seals

- Heavy duty aluminum doors

- Easy access for service and maintenance needs

OPTIONS & ADD-ONS:

- Easy-to-use LCD touchscreen interfaces

- Adjustable microprocessor-controlled cycle times

- Automatic push button doors are available

- High speed roll up doors are available

-

Air shower helps reduce the risk of defects to products and can also increase cleanroom production yields. Air showers improve cleanroom performance and reduce the maintenance needed to maintain a clean environment by minimizing the overall contamination load in the area.

If a cleanroom doesn’t use an air shower's “pre-cleaning” process, its air filtration system would have to absorb all of the contaminants in the environment. That would increase energy consumption and maintenance costs for the cleanroom.