INDUSTRY NEWS

Cleanroom Technology for the Pharmaceutical Industry

Laminar flow hoods for the pharmaceutical industry

The A-level traffic produced by our company is cost-effective:

1. Different metal materials (such as stainless steel) can be used for the outer frame.

2. The assembled centrifuge has a variety of models to choose from, and it has the characteristics of low noise and low energy in actual work.

3. Choose a good anti-static plastic heavy curtain, which has the characteristics of good anti-static effect, high transparency, good flexibility and not easy to deform and age.

4. Applicable to local decontamination level requirements of Class 10-100 (US Federal Standard 209E).

As a pioneer of clean technology, our company has many years of experience in the design and production of clean equipment. Our R&D team consists of experienced engineers, the production line adopts a strict quality control system, and all production procedures are carried out according to ISO 9001. Our products have a high reputation and can provide you with the best cost-effective topical decontamination solution.

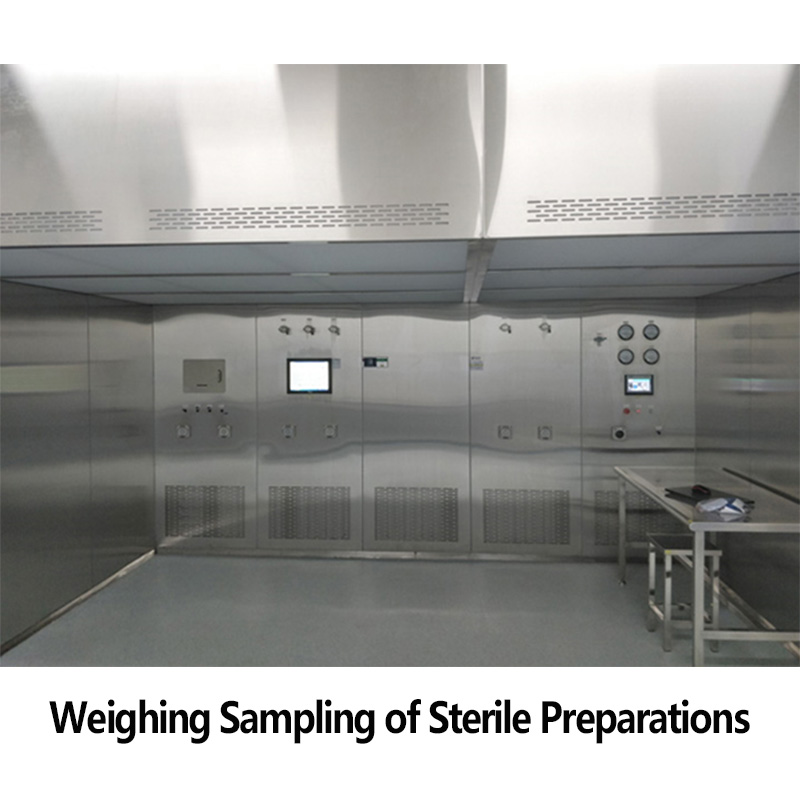

Weighing hoods for the pharmaceutical industry

Negative pressure weighing hoods are widely used in the pharmaceutical industry. The weighing hood provided this time is mainly used for weighing and data recording of APIs and drug samples.

Recorded, the negative pressure environment makes the clean environment inside the weighing hood reach Class A cleanliness, which not only ensures that the drug samples are not polluted, but also effectively saves production costs. In addition, our company can also provide weighing hoods that meet the OEB3 standard, as well as anti-corrosion and explosion-proof weighing hoods.

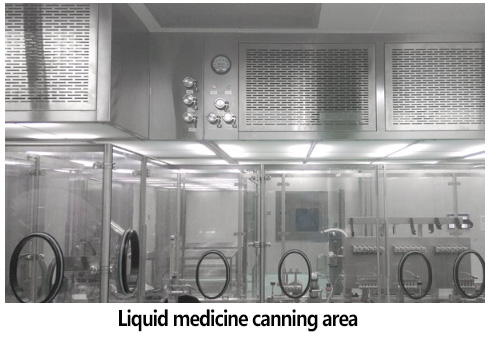

Laminar flow hoods for the pharmaceutical industry

In this pharmaceutical factory project, the laminar flow hood provided by our company is mainly used in filling and sub-packaging area, finished product inspection area, packaging area, etc. After receiving the project, our company's design and development personnel evaluated the workshop site environment, conducted demand analysis for the required A-level and B-level laminar flow hood areas according to the site conditions, and drew up the system design to present the best to customers. solution.

After the design plan is determined, the laminar flow hoods at all levels quickly arrange standardized processes such as production, testing, and quality inspection. The laminar flow hood produced by our company is of modular design, and the modules are separately packaged and transported at the factory, which is safer and more convenient. After the equipment arrives in the market, a special person will be arranged to guide the installation and debugging operation at the project site to ensure the normal operation of the laminar flow hood.