COMPANY NEWS

Why do hospitals use air filters?

The medical and health industry is a very large and special industry. In each department of a medical institution, the demand for air filters may vary. The air filters produced by Jiefeiran are different in hospitals. All departments have applications, and hospitals have high requirements for air cleanliness. Different air filtration solutions need to be designed according to specific needs. Below, we make a general summary of common air filter applications in hospitals. For specific needs, product parameters, and applications, please contact us.

01 Filtration of air supply and ventilation system in public areas of hospitals

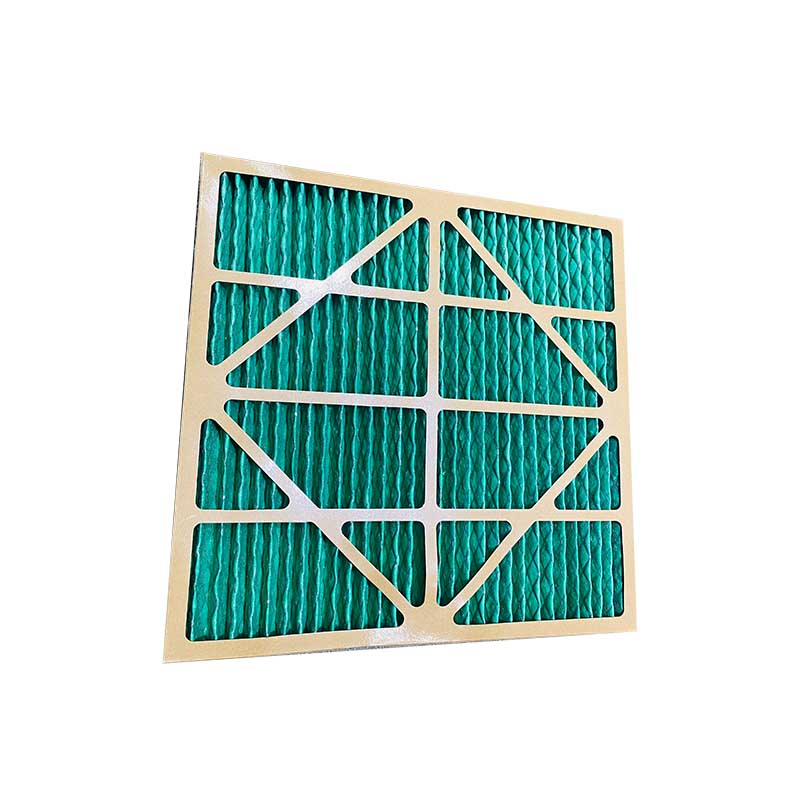

For the filtration of fresh air ventilation systems in public areas of hospitals and general office areas, primary and medium-efficiency filters are generally used.

02 Air filtration in hospital preparation center

The preparation center of the hospital is a special clean place for medical units to prepare preparations/drugs. The purified air used in the clean area should meet the requirements of the preparation process and preparation quality, and reach the cleanliness level stipulated in the "Good Manufacturing Practice for Drugs" (referred to as GMP). That is to say, the cleanliness of the preparation center is equivalent to the requirements of the pharmaceutical factory. The cleanliness level of the filling and sealing positions is 100, and the final processing positions of the packaging materials for dilute preparation, filtration and direct contact with medicines are 1000. Posts such as quantity and ingredients should be 100,000 grades. Therefore, the demand for air filtration in the preparation center is quite large, covering almost all filters with high filtration efficiency levels in junior high schools.

03 Intravenous drug distribution center, horizontal purification workbench, biological safety cabinet

The Intravenous Drug Allocation Center (PIAS) is an institution built according to the national 10,000-level clean room standard, and is an organization that regulates the allocation of intravenous drugs such as total intravenous nutrition, cytotoxic drugs, antibiotics and antibiotics. The filters used are: primary filter, medium-efficiency filter, high-efficiency filter and purification and exhaust system.

04 ICU ward, general ward air filtration

The purification level of ICU intensive care unit is usually divided into: 10,000-level, 100,000-level, 10,000-level ventilation times 20-25 times/H, and 100,000-level ventilation times 10-15 times/H, all using positive pressure laminar flow purification In the air supply mode, the filters that need to be used are: primary efficiency filter, medium efficiency filter, high efficiency filter, equalizing membrane and purification and exhaust system. In addition, ordinary wards also use this laminar flow cleaning mode.

05 Air filtration in bone marrow transplant ward

The bone marrow transplant ward, also known as the sterile ward, adopts the form of a closed single compartment. It is the ward with the highest requirements for protective isolation measures. Because the immune system of bone marrow transplant patients is imbalanced, the ordinary indoor air will also endanger the life safety of the patients. Therefore, The bone marrow transplant ward needs to use positive pressure laminar flow cleaning to ensure the air safety of the ward. The main air filters used in the air purification system of the bone marrow transplant ward/sterile ward are: primary filter, medium efficiency filter, high efficiency filter, flow equalizing membrane and purification and exhaust system.

06 Air filtration in infectious disease room

In addition to ensuring indoor air safety, infectious disease wards also need to ensure indoor air and controlled emissions. Therefore, a negative pressure system is set up to ensure that indoor air will not flow in and out of medical staff and overflow outdoors through doors. In addition to using: primary filtration In addition to filter, medium-efficiency filter, high-efficiency filter, and flow-equalizing membrane, it is also necessary to use BIBO bag in and out of the safety filter.

07 Laminar flow purification operating room air filtration

Multi-stage air pre-filtration (primary filter, medium-efficiency filter) is set at the front end of the air conditioning/ventilation system, and the high-efficiency filter without partition is set directly above the operating table, and the filtered clean air passes through the flow-equalizing membrane to The uniform flow rate is conveyed in the preset direction, and a slight positive pressure is maintained to continuously ensure that the operating table meets the corresponding cleanliness requirements. The return air outlet of the exhaust system is usually set at the four corners of the wall to ensure the complete circulation and filtration of the indoor air.