COMPANY NEWS

Discussion on the design of MAU+DCC+FFU system for purification air conditioning

Discussion on the design of the MAU+DCC+FFU system for purification air conditioning

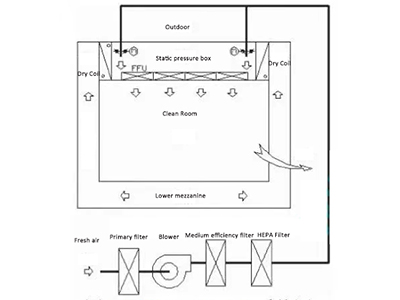

The MAU+FFU+DC system is a combined fresh air unit (Make-up Air Unit) + fan filter unit (Fan Filter Unit) + dry coil (Dry coil) system.

The most common form is shown in Figure 1

Due to its characteristics of temperature zone control, flexible layout, FFU negative pressure sealing, and energy saving of return air delivery, it is very suitable for the characteristics of large heat-humidity ratio (extremely large heat load and small heat dissipation), large return air volume, and large-area purification in electronic factories, and is therefore widely used in the design of electronic clean factories. In the actual design and engineering installation process, the author has come into contact with many such systems and found that many similar projects currently lack clear basis and data as reference in the design engineering (the specifications do not have detailed regulations and requirements), and even many projects have conflicts between design and specifications. Therefore, it is necessary to further explore some issues.

1.1 Main factors of negative pressure formation

The upper static pressure box of FFU is negative pressure relative to the room, which can play the role of negative pressure sealing. This is also a recognized advantage of the FFU system. Of course, this is also the case in MAU+FFU+DC.

However, in general engineering projects, the static pressure box of FFU is also negative pressure relative to the outside (for this reason, the author has done tests). Especially in the FFU static pressure box of the MAU+FFU+DC system, due to the return air passing through the dry coil, there is a large wind pressure loss (there is data or it is generally believed to be 30 Pa ~50 Pa, which will be analyzed in detail in Section 2); under the condition of ensuring a certain positive pressure value indoors (such as the clean area and non-clean area are not less than 10 Pa according to the specification), it is bound to cause the FFU static pressure box to be negative pressure relative to the outside. For example: if +10 Pa is guaranteed in the clean room (relative to the outdoor non-clean area), the return air orifice and the return air channel wind pressure loss is 5 Pa, and the wind pressure loss of several coils is 40 Pa, then it can be known that the pressure in the static pressure box is -35 Pa (relative to the outdoor non-clean area).

Therefore, we can draw a conclusion, but also a question. First, the main reason for the negative pressure in the static pressure box is the wind pressure loss of the dry coil (the return air duct and orifice plate resistance loss are relatively much smaller). Second, is the negative pressure in the static pressure box (relative to the outdoor non-clean area) reasonable?

1.2 Discussion on negative pressure in static pressure box

The static pressure box on the upper part of FFU is negative pressure relative to the room, which can play the role of negative pressure sealing, which undoubtedly plays a positive role in ensuring cleanliness in the clean area. However, it is negative pressure relative to the outdoor non-clean area (generally the technical interlayer), which will inevitably cause outdoor air to leak directly into the static pressure box, affecting the service life of the FFU filter, which is undoubtedly harmful or unfavorable.

This situation is actually equivalent to placing the FFU in the negative pressure section (relative to the outdoor non-clean area). This conflicts with the provisions of GB 50073-2001 "Clean Plant Design Code".

First, Article 6.4.1 stipulates that medium-efficiency (high-efficiency) air filters should be concentrated in the positive pressure section of the air conditioning system. The reason is that it is considered that the negative pressure section is prone to air leakage (see the article explanation); what's more, FFU generally contains high-efficiency or ultra-high-efficiency filters. Secondly, the fresh air of the MAU+FFU+DC system is filtered by high-efficiency filters and then mixed with the clean return air in the static pressure box, which means that the static pressure box is still a clean area, or at least a quasi-clean area (this can be known through calculation). Article 6.2.2 requires that the pressure difference between clean rooms of different levels and between clean areas and non-clean areas should not be less than 5 Pa, and the pressure difference between clean areas and the outdoors should not be less than 10 Pa.

In engineering design, it is necessary to make a comprehensive comparison from multiple aspects such as economy (including cost and operation), advancement (technical aspects), and energy saving to determine whether it is reasonable or not. It cannot be viewed from a single aspect. Most of the specifications in design engineering designs follow this principle when selecting technical means and determining certain parameters. Therefore, it is reasonable for the FFU static pressure box to have a certain negative pressure relative to the outdoors (see the specific calculation analysis below), which is also consistent with the guiding ideology of engineering design. The key to the problem is how to determine this negative pressure value? Let's call it the economic value for the time being. The rationality and economy of this value are what we care about most.

2 Dry coil selection

As we know from 1.1, the dry coil is the main factor causing the negative pressure of the FFU static pressure box (relative to the outdoor non-clean area), and the negative pressure value determines the service life of the FFU filter and the size of the dry coil area. Through the above analysis, the negative pressure value of the FFU static pressure box needs to be controlled within a range of less than or equal to 20 Pa. At this time, while ensuring the service life of the FFU filter, the dry coil area is the smallest (that is, the investment is the least).