PRODUCT

Equipment Type and Purpose:

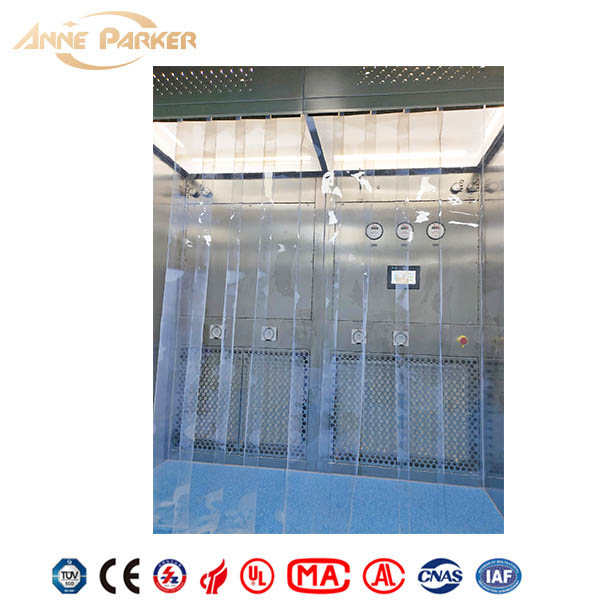

The negative pressure dispensing booth is a high-performance device used in pharmaceutical, micro-electronics,

and scientific research laboratories. It provides vertical unidirectional airflow. A portion of the clean air recirculates

within the work zone, while another portion is exhausted to the surrounding area, creating a negative pressure

in the work zone to prevent cross-contamination. It is used to ensure the cleanliness of the work zone and for material handling.

Automatic Wind Speed Variable System maintains uniform and stable airflow velocity in the work zone.

Filter and Flow Monitoring Device for real-time monitoring of the effective operation of each filter stage.

Low Noise Design effectively controls the overall operating noise of the unit.

Safety Protection Function Design: Includes failure rate assessment, test alarms, separation, controllable inspection,

reagent detection, exhaust, protective measures, protection against hazards to personnel, transport safety, prevention

of reagent cross-contamination, and protection of the external environment and personnel safety. Provides overall

protection compliant with Class 100 ISO standards (NF, EN, ISO 14644-1) during operation.

Operating Environmental Conditions:

Temperature: 5°C – 40°C

Relative Humidity: ≤75% (Non-condensing)

Atmospheric Pressure: 86–106 kPa

Power Supply: AC 380V, 3-phase, 50HzTechnical Parameters:

-

-

Internal Dimensions: 3900mm (W) × 2460mm (D) × 1900mm (H)

External Dimensions: 4000mm (W) × 3100mm (D) × 2400mm (H) -

Main Material: 12mm thick SUS304 brushed stainless steel plate, bent and formed.

-

Rated Airflow (m³/h): 12430 ~ 18650

-

Outlet Air Velocity (m/s): 0.45 ± 20%

-

Rated Power (kW): 13.5 (includes backup power function)

-

Noise (dB(A)): < 75

-

Built-in LED Illumination (Lux): ≥ 300

-

Power Supply: 380V, 50Hz

-

Controller: Siemens PLC control with LCD display control panel

-

Control System: Automatic variable frequency system for wind speed.

-

Pre-filter: G4 efficiency, non-woven fabric

-

Medium efficiency filter: F8 efficiency, bag type

-

HEPA filter: H14 efficiency, gel seal and mini thread (with PAO detection port)

-

Three differential pressure gauges (Dwyer brand)

-

Four HEPA filters at the exhaust vents

-

Removal-to-filter cutoffs

-

Wind speed sensor (E+E / KIMO)

-

Factory-set level 3 password

-

Component List:

| No. | Component | Specification/Model | Qty. | Brand/Note |

|---|---|---|---|---|

| 1 | LED lamp | T5 | several | Philips |

| 2 | Start switch | VJ-QQ1(H+1) | 1 | Anne Parker |

| 3 | E-stop | Solmolder Electric | 1 | Anne Parker |

| 4 | Switched socket | IP66 | 8 | Jung/brand |

| 5 | LCD control panel | T-motor | 1 | Johnson |

| 6 | Primary efficiency filter | G4 | 4 | Anne Parker |

| 7 | Medium efficiency filter | F8 | 4 | Anne Parker |

| 8 | Gel seal HEPA filter (exhaust) | HH4 | 4 | Anne Parker |

| 9 | Gel seal HEPA filter (supply) | HH4 | 12 | Anne Parker |

| 10 | Detection port | 6-point clamp | 4 | 304 SUS |

| 11 | Injection port | 6-point clamp | 4 | 304 SUS |

| 12 | Differential pressure gauge | 0–500 Pa | 3 | Dwyer |

| 13 | Frequency converter | ABB brand | 1 | 360X 5-Kw |

| 14 | Fan | DKT159-56 | 2 | Shanghai Yingda |