Chemical (AMC)Filter

Airborne Molecular Contamination (AMC) Chemical (AMC)Filter Introduction

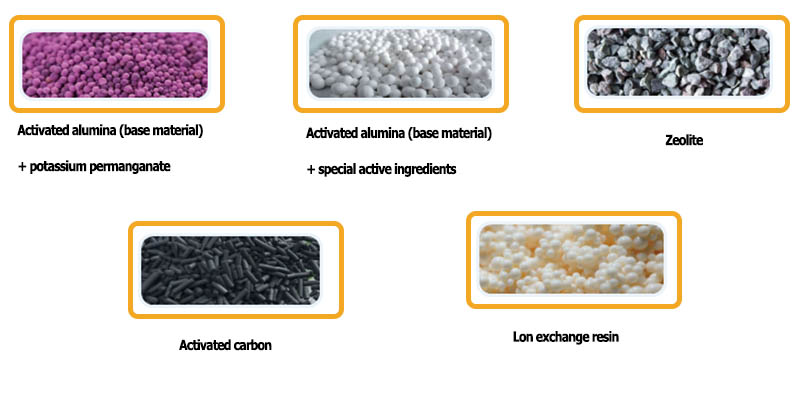

Activated alumina (base material) + potassium permanganate

Removes pollutants such as hydrogen sulfide, sulfur dioxide, formaldehyde, and other sulfur oxides

Activated alumina (base material) + special active ingredients

Removes gaseous halogens, chlorine, bromine, and iodine

Zeolite

Removal of ammonia

Activated carbon

Hydrocarbon gases, volatile organic compounds, chlorine, and nitrogen dioxide

Lon exchange resin

Strong acidic cations remove ammonia; strong alkaline anions remove H2S, etc.

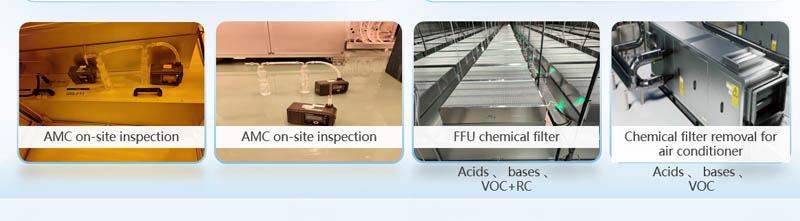

Pretreatment chemical filters

| Activated carbon media | AKV-VOC | AKC-Acid | AKA-Base |

| Size | 594*594*50mm | ||

| Frame | Frame 45mm (50mm with sealing gasket) | ||

| Plastic Frame | GI | GI | GI |

| Medium | 700g/m³ | 700g/m³ | 700g/m³ |

| Activated Carbon Granules | TA85 | ABE | AM |

| Rated wind speed | 0.7 | 0.7 | 0.7 |

| Initial resistance | 32pa | 32pa | 32pa |

| Gross weight | 5.5kgs | 5.5kgs | 5.5kgs |

| Medium area | 2.0/㎡ | 2.0/㎡ | 2.0/㎡ |

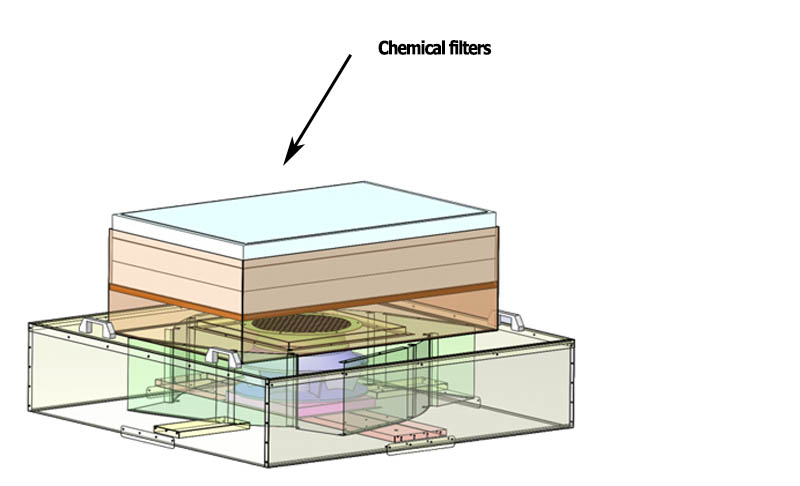

FFU supporting chemical filter

| Activated carbon media | AKV-VOC | AKC-Acid | AKA-Base |

| Size | Customized | Customized | Customized |

| Frame | Customized | Customized | Customized |

| Plastic Frame | GI-ALU-SUS | GI-ALU-SUS | GI-ALU-SUS |

| Medium | 300-800g/m³ | 300-800g/m³ | 300-800g/m³ |

| Activated Carbon Granules | TA85 | ABE | AM |

| Rated wind speed(m/sec) | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 |

| Initial resistance | 32-120pa | 32-120pa | 32-120pa |

Filtration treatment of chemical gaseous molecular pollutants in external air. The main gaseous molecular pollutants in external air

are sulfur oxides, hydrogen sulfide, nitrogen oxides, ammonia, and organic volatiles

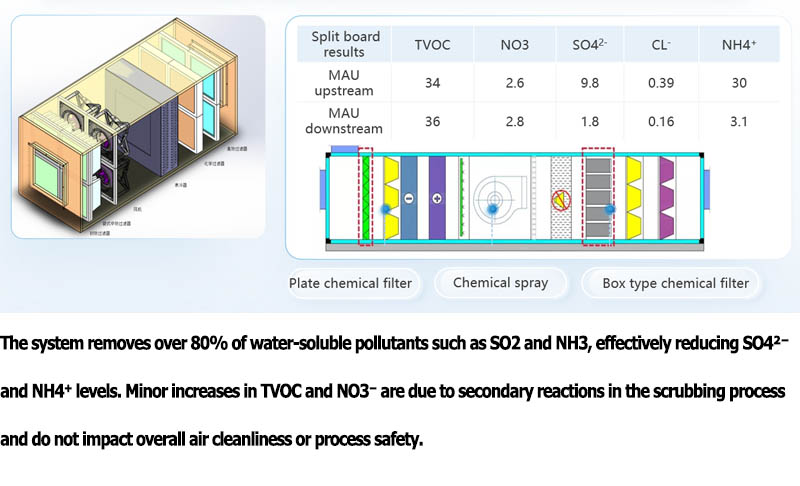

Chemical spraying can preferentially absorb water-soluble AMC chemical pollutants through water washing. The absorption rate

of sulfur dioxide by water washing spray is over 82%.

Filtration and treatment of chemical gaseous molecular pollutants inside the clean system. The main chemical

molecular pollutants inside the clean system are acids, alkalis, VOC+RC

Chemical molecular pollutants generated inside the clean room system are self-circulated through the FFU

After the air inlet of the FFU is filtered through the chemical filter, the air is pushed by the fan and filtered through the HEPA filter

before entering the clean room, ensuring that the production process control environment in the clean area is controlled within the concentration

and the life range designed by the chemical filter.