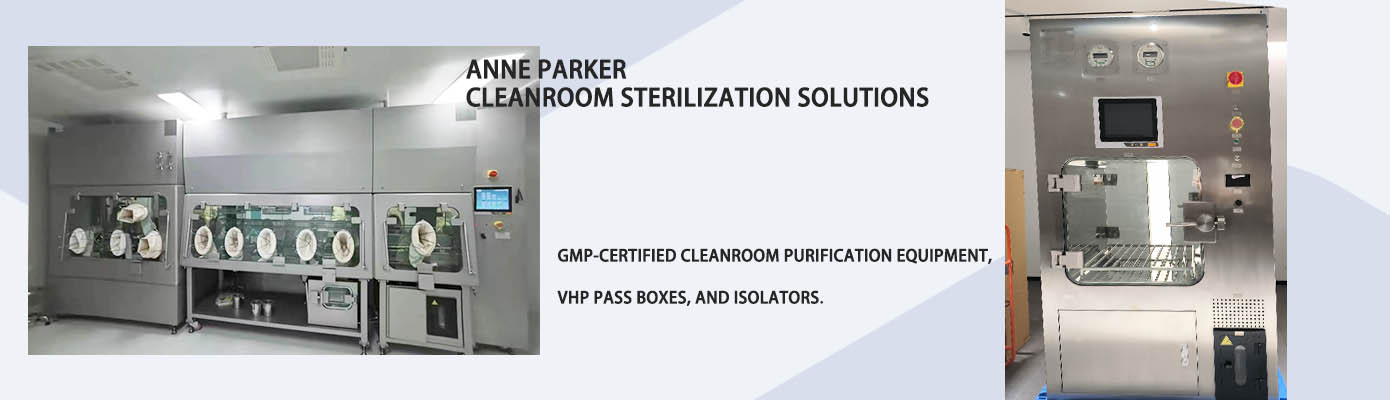

VHP Sterilization Solutions

- 1/1

VHP Sterilization Solutions

1. High-Efficiency Sterilization

Utilizes VHP (vaporized hydrogen peroxide) sterilization technology, achieving a kill rate of up to 6 log, suitable for GMP/BSL-3/4 requirements.

2. Compliance with International Standards

Complies with cleanroom standards such as EU GMP, FDA, WHO, and ISO14644.

3. Wide Range of Applications

Biopharmaceutical, vaccine, laboratory, animal health, and sterile preparation plants.

4. Safety and Automation

Fully automated VHP sterilization cycle with multi-point concentration monitoring.

Equipped with electronic interlocks to prevent cross-contamination.

5. Customization

We offer 304/316L stainless steel materials, custom sizes, and intelligent control systems to meet specific customer needs.

Highly Efficient Sterilization

Our VHP pass box can quickly and thoroughly kill a wide range of microorganisms, achieving a sterilization rate exceeding 99.999%,

providing reliable microbial control for biopharmaceutical production environments. Precise concentration control is ensured.

The interior and exterior surfaces, as well as the frame, are constructed from 304 cold-rolled stainless steel with a

thickness of ≥1.5mm and polished to a surface finish of at least RA1.2. The frame, with a thickness of ≥1.2mm, is also

polished to ensure seamless connections, corrosion resistance, and easy cleaning. The viewing window is constructed

from tempered glass with a thickness of ≥8mm, providing durability and easy internal visibility. The VHP pass box is

highly compatible with existing biopharmaceutical production processes and equipment, allowing for easy installation

and rapid integration into production systems, improving overall production efficiency.

Biotech companies have stringent requirements for cleanroom cleanliness in their R&D and production. During the

transfer of items from non-clean areas to clean areas, it is crucial to ensure that no contaminants are introduced.

while also ensuring fast and efficient transfer to improve overall production efficiency.

In the pharmaceutical industry, the cleanliness of the production environment is directly related to

drug quality and safety, and the risk of microbial contamination cannot be tolerated at any stage.

A pharmaceutical company has seen significant improvements after implementing our VHP pass box.

Before material transfer, the VHP pass box initiates a sterilization process, using hydrogen peroxide vapor to

fully decontaminate the exterior surfaces of materials and equipment, effectively killing any potential microorganisms.

This effectively prevents microbial contamination introduced during material transfer and ensures a stable environment

within the high-level cleanroom. This not only improves quality consistency during drug production but also reduces

product quality issues and financial losses caused by microbial contamination.

Isolator sterilization system

A cell preparation isolator system allows the production of cell therapy drugs to be carried out within a fully enclosed area,

including reagent preparation, cell pretreatment, cell culture centrifugation, cell microscopy, and environmental monitoring.

The cell preparation isolator workstation can be installed in a Class D cleanroom. Its compact design effectively saves space,

eliminating the need for large-scale spatial layout modifications and reducing facility construction costs. Currently, our isolators

are widely used in cell therapy research projects at scientific research institutions and in the cell therapy production process

of biopharmaceutical companies. They play a vital role in promoting the development and application of cell therapy

technology, enabling relevant institutions and companies to conduct cell therapy-related work efficiently and safely,

and contributing to the fight against difficult diseases and improving human health.

In the field of cell therapy

Leveraging AnneParker's expertise in cell preparation process optimization and compliant production, we provide comprehensive,

end-to-end solutions for the preparation and production of immune cell, stem cell, and tumor cell vaccines, from laboratory

development to commercial production. This helps cell therapy products rapidly enter the clinic and benefit patients.

In the field of gene therapy

We address key technical challenges in the development and commercialization of nucleic acid (mRNA/DNA) and viral

vector-based drugs, creating a customized technology platform that provides comprehensive solutions encompassing

vector construction, large-scale production, and quality control, accelerating the industrialization of gene therapy technology.

Ultra-High-Fit Gloves

The two-section glove design provides a better fit for the hand and is suitable for delicate manipulation.

Fully Enclosed and Isolated

This achieves temporal and spatial isolation between cell therapy production batches, preventing direct human interaction

and ensuring greater compliance with regulatory requirements for sterility assurance. Samples, personnel, and the

environment are completely isolated to prevent cross-infection and meet safety requirements.

Grade A Environmental Assurance

Provides Grade A quality throughout the entire cell preparation process. Grade D sterility assurance ensures the

sterile production environment requirements for cell-based therapeutics.

Real-time online environmental monitoring

Online monitoring of the sterile production environment ensures regulatory compliance and enhanced sterility assurance.

Customized and modular design

Customized solutions are available based on different cell-based therapeutic production processes and production scheduling

requirements. Modular combinations are available to meet diverse process requirements to form a cell production platform.

Cost and space savings are achieved.

Can be used in environments as low as Grade D, reducing plant investment and operating costs, streamlining personnel

change procedures, and improve efficiency and comfort.

Easy to clean, improving efficiency.

Easy to clean and validate, enabling rapid batch changes to meet the needs of multiple products on the same production line.

Sterilization system

Utilizing our company's patented technology, integrated VHP sterilization technology achieves efficient sterilization at room temperature and pressure.

Full Data Recording

A control system records key parameters and ensures traceability.

Fast Delivery

Rapid VHP sterilization delivery technology enables rapid sterilization within 8 minutes, providing faster and

more professional services to the biopharmaceutical industry.