PRODUCT

VHP Compounding Aseptic Containment Isolator

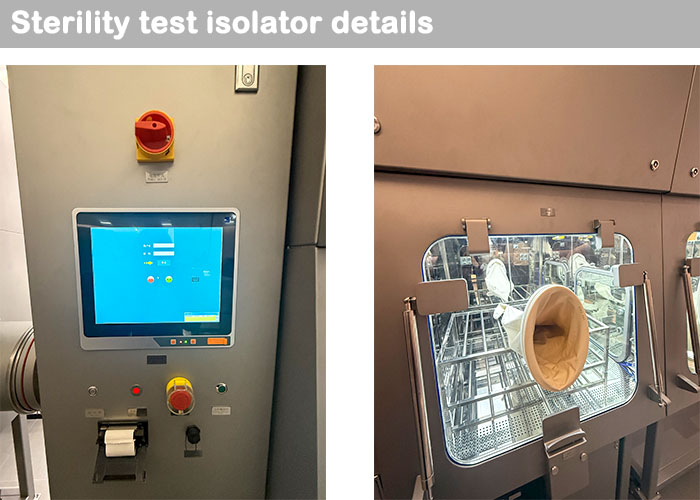

Aseptic inspection isolator is designed and produced for the aseptic inspection process of aseptic products, highly integrated equipment and instruments, simple operation, shorten the disinfection and sterilization time, greatly save the overall test time.

VHP Compounding Aseptic Containment Isolator

Product application

Aseptic inspection isolator is designed and produced for the aseptic inspection process of aseptic products, highly integrated equipment and instruments, simple operation, shorten the disinfection and sterilization time, greatly save the overall test time, to achieve the shortest sample flow time between production and testing, and provide good environmental control to achieve the least false positive interference in the process of aseptic test.

The VHP isolator system provides a low-cost and efficient clean inspection environment in a limited laboratory environment to ensure product sterility requirements, ensure rapid product sterilization function of sterile inspection and sterile operation.

Other process operations such as aseptic distribution/sampling, aseptic product transfer can also be performed under aseptic conditions within the aseptic isolator system.

Protection type: Protection product.

Product function

1. Complete sterility test technology, such as VHP sterilization, sterilization cycle verification, bacteria collector and consumables, microbial consumables and other complete services.

2. Multi-station operation, such as single-sided or double-sided, can be tested 10 to 40 times a day.

3. Both the transfer cabin and the operation cabin are stepwise positive pressure systems, and the air flow is organized as turbulence or laminar flow. Fresh air is taken from the C-level environment (pre-filtration) or HVAC system, unidirectional turbulence or laminar flow is formed through HEPA(H14), and it is circulated or discharged through the return air system.

4. Continuous and large-scale sterility inspection can be carried out, and biological sterilization can be carried out respectively or simultaneously in the transfer cabin and the operation cabin to improve sterilization efficiency.

5. The isolator and the hydrogen peroxide sterilizer are managed by the same control system, which ensures repeatability and reliability of operation. The single operating system and easy to operate panel ensure easy operation, reduce the possibility of error, and improve efficiency.

6. Through the intelligent sterilization reservation function, the sterilization time can be effectively saved, and the sterilization efficiency of multiple batches can be improved every day. In the sterilization process, the processes of dehumidification, regulation, sterilization and ventilation and exhaust residue are automatically operated by HM1 to avoid human errors. Can quickly achieve log6 microbial killing effect, to ensure that through the challenges of CI and BI.

Built-in process formula collector

The electrical system is installed outside the isolator to minimize corrosion of the collector wiring and electronic components by chemical gases during sterilization.

The completely sealed structure ensures that there is no risk of leakage inside the bacteria collector and avoids cross-contamination.

Process formula management, one-click operation, intelligent memory and result output.

Integrated dust particle counter, built-in PU tube and connected device interface, truly plug and play.

Integrated plankton sampler, using standard AGAR plate, external pipes are loop and switching design, so that there is no dead Angle sterilization.

The modular dry VHP sterilizer uses flash technology to achieve true vaporization, assisted by process vapor saturation control to avoid condensation and corrosion.

Built-in hydrogen peroxide catalytic decomposer reduces hydrogen peroxide residue to 1ppm, resulting in safe emission and automatic recovery.

Product parameters

|

Model |

INNOVE-GLQ-2650-2A |

INNOVE-GLQ-2650-2B |

|

External dimensions W*D*H |

2650*750*2250 |

2650*1200*2250 |

|

Transfer cabin dimensions W*D*H |

850*600*800 |

850*600*800 |

|

Operation cabin dimensions W*D*H |

1800*600*800 |

1800*1200*800 |

|

Glove station |

4 gloves, circular port, HYPLON gloves |

8 gloves, circular port, HYPLON gloves |

|

Air distribution |

Both the transfer cabin and the operation cabin are laminar flow (class A) |

|

|

Sterilization efficiency |

Thermophilic spore 10log6 killing effect, high concentration >500ppm, low concentration <1ppm, sterilization cycle: 3h |

|

|

Gate system |

interlock system |

|

|

Filter |

G4 primary filter + H14 HEPA filter + hydrogen peroxide decomposition filter |

|

|

Control system |

PLC intelligent control system |

|

|

Intelligent monitoring |

Isolator cavity pressure difference / HEPA filter pressure difference / Wind speed on the outlet side / Leakage rate per hour / High or low concentration of hydrogen peroxide |

|

|

System integration |

On-line monitoring of dust particles, plankton, etc |

|

|

Leakage rate per hour |

<2.5*10³ |

|

|

Power demand |

220V/5KW |

|