INDUSTRY NEWS

What are the Equipment Required for the Clean Room?

Clean room, also known as clean room, clean room or clean room. It is the foundation of pollution control. Without a clean room, mass production of contamination-sensitive parts is impossible. In FED-STD-2, a clean room is defined as a room with air filtration, distribution, optimization, construction materials and devices, in which specific regular operating procedures are used to control the concentration of airborne particulates in order to achieve proper particulate cleanliness degree level.

So, what equipment is required for a clean room? (names not listed in order)

1 Air Shower

The air shower room series is a kind of local purification equipment with strong versatility, which is installed between the clean room and the non-clean room. When people and goods want to enter the clean area, they need to be blown through the air shower, and the clean air blown out can remove the dust carried by people and goods, and can effectively block or reduce the dust source from entering the clean area. The front and rear doors of the air shower/cargo shower are electronically interlocked, and can also act as airlocks to prevent unpurified air from entering the clean area.

2 Cargo Shower Room

The cargo shower room, as the name implies, is a special blowing shower room for goods, also known as the cargo shower channel and the cargo shower door. It is widely used in the logistics channels of electronic, food and packaging enterprises. The raw materials and tools of the processed goods are blown and showered to achieve the effect of filtering and removing dust particles, and the raw materials entering the dust-free workshop are clean. Due to the size of the site of each enterprise's logistics channel and the size of the transportation method of the raw materials that need to be blown and showered, so There is no uniform standard for the cargo shower room, and all are non-standard products. In terms of function, the cargo shower includes ordinary type cargo shower room, infrared voice prompt type cargo shower room, and automatic sliding door type cargo shower room.

3 Pass Box

The pass box is mainly suitable for the transfer of small goods between the clean area and the non-clean area, or between the clean room and the clean room, which can effectively reduce the opening times of the clean room door and minimize the pollution in the clean area. According to the requirements of use, the surface of the transfer window box can be sprayed with plastic, and the inner tank can be made of stainless steel, with a beautiful appearance. The two doors of the transfer window are equipped with electronically controlled interlocking or mechanical interlocking devices, which can effectively prevent the dust in the low cleanliness area from being brought into the high cleanliness area. It is a must-have product for purification workshops.

4 Efficient Air Outlet

This product is a terminal air supply device for the purification air conditioning system of the 10,000-level and 100,000-level turbulent clean rooms for new construction and reconstruction projects. It can be widely used in purification and air conditioning systems in the electronics industry, precision machinery, metallurgy, chemical industry and other industries, as well as in medical, pharmaceutical, food and other sectors. The device is mainly composed of static pressure box, high-efficiency filter, aluminum alloy diffuser plate, standard flange interface, etc. It has beautiful appearance, simple structure and reliable use. The air outlet is bottom-mounted, which has the advantage of convenient installation and replacement of filters in the clean room. The high-efficiency filter adopts mechanical pressing or liquid tank sealing device to ensure that the air outlet is installed without leakage, has reliable sealing and good purification effect, and is suitable for general purification. works are applicable.

5 Clean Workbench

The clean workbench in the dust-free workshop can maintain local purification with high cleanliness on the operating table according to the requirements of the product or other purposes. The clean workbench can form aseptic and dust-free local purification in the local space of the operating table. Its main components are pre-filter, high-efficiency filter, fan unit, shell, static pressure box, table and supporting electrical components, etc. .

Structural requirements of the clean workbench in the clean room: the countertop is made of wood and plastic veneer and pasted on the laminate to make the countertop, or stainless steel is used as the countertop; The rolled sheet is folded and lapped, welded with high current, and the inner surface needs to be pasted with sound-absorbing material. The maximum size should be suitable for passing through a general door; the box is sealed, and all gaps are sealed with sealant; the section of the operating area should be as close to the air as possible. The air supply section of the filter is the same, and the blind area is minimized; for the fan and motor, a small fan with high pressure and low noise is selected, the connection between the fan and the box body adopts a soft connection, and vibration reduction measures should be taken for both the motor and the fan; In the lampshade, clean air should pass through the lampshade; pre-filter should be set with a pre-filter with a large capacity, and the initial resistance should be less than 50Pa under the use of air volume; high-efficiency filter, try to use a large-area filter to reduce air filtration Depending on the number of filters, the seal between the filter and the frame should be a double-ring seal system combined with seal and guide.

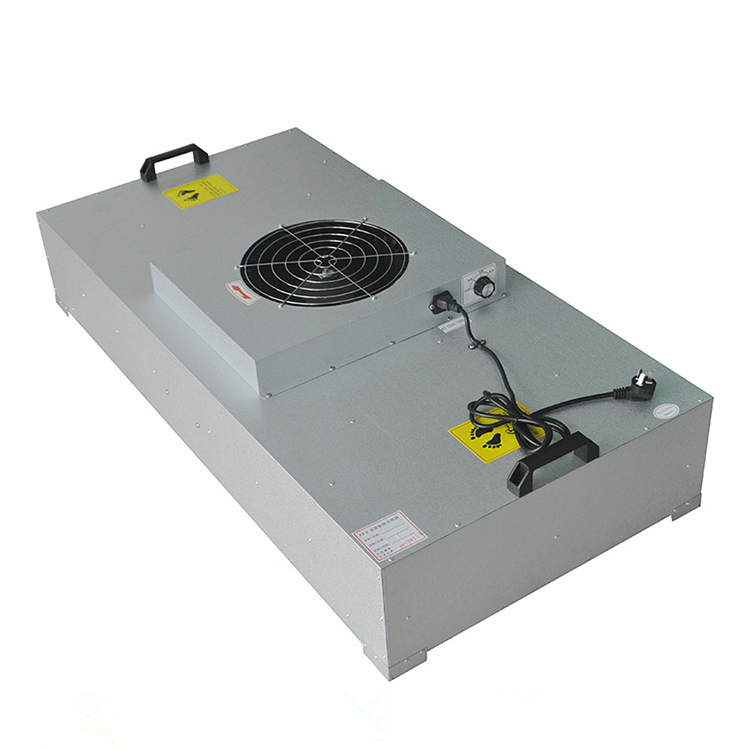

6 FFU fan filter unit

Fan filter unit (FFU) is an air self-purification device, which can be installed on indoor ceiling or placed on a bracket, so that the local level can reach 100. It can also be used to supply air at the end of the clean room. The product is equipped with primary and high-efficiency two-stage filtration device. The fan inhales the air from the top and filters it through the primary and high-efficiency filters, and the filtered clean air is sent out through the entire air outlet. There are two installation methods: hanging and floor brackets.

The fan inhales the air from the top of the FFU and filters it through the primary and high-efficiency filters. The filtered clean air is sent out at a uniform speed of 0.45M/S±20% on the entire air outlet surface. It provides high-quality clean air for clean rooms and micro-environments of different sizes and cleanliness levels. In the renovation and renovation of new clean rooms and clean workshops, it can improve the cleanliness level, reduce noise and vibration, and greatly reduce the cost. It is easy to install and maintain, and it is an ideal component for a clean environment.

7 Laminar Flow Hood

Laminar flow hood is an air purification device that can provide a local high clean environment. It mainly has a box, a fan, a primary air filter, and a high-efficiency air filter. Damping layer, lamps and other components, the box is sprayed or made of stainless steel. The product can be suspended or supported on the ground, with compact structure and convenient use. It can be used singly or connected in multiples to form a strip-shaped clean area. Widely used in precision machinery, electronics, pharmaceuticals, food, fine chemicals and other departments.

If you need the above clean room equipment, please contact us.