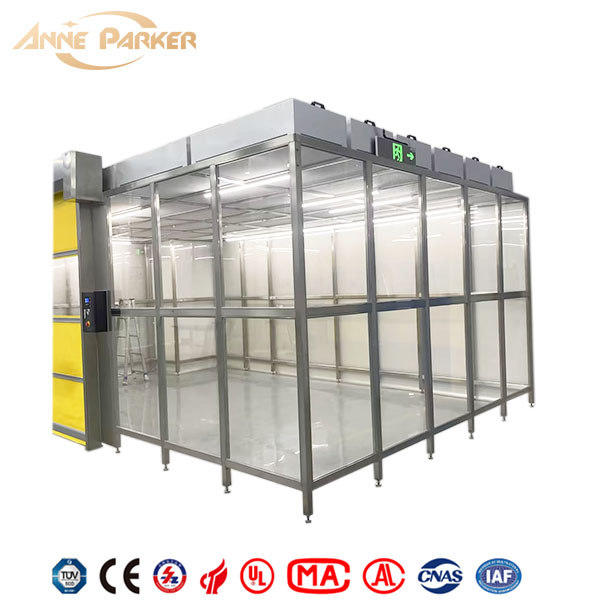

PRODUCT

Class 100 class 10000 modular cleanroom system manufacturer

We will shoot a good installation video for large modular cleanrooms for customers.

Technical configuration description:

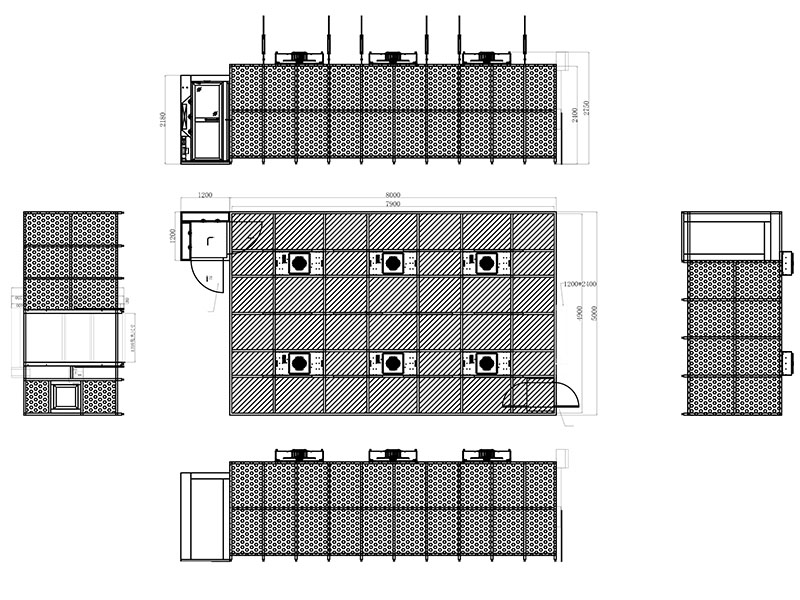

1. External dimensions: W5000xD8000xH2750

Inner dimensions: W4900xD7900xH2400

2. Material:

a. The bracket is fixed with 50*50 SUS304 sanded stainless steel square tube

b. 6 FFUs are laid on the top surface, and the rest are sealed with 304 stainless steel plates

c. PVC anti-static mesh curtains are used around the bracket

3. FFU fan filter unit

a. External dimensions: 1175*575*350

6 units

b. The outer shell is bent and formed with an aluminum-zinc plate

c. XM-310 DC fan single unit noise: ≤ 65 dB

The impeller is a vortex structure, made of aluminum alloy

d. 6 sets of aluminum frame non-partition filter (1170*570*69), efficiency (H14) 99.995%@0.3um

e. Stepless speed regulation, wind speed at air outlet 0.35-0.54m/s

f. Total input power: AC220V50Hz 150W*6 sets

4. Equipped with a set of rolling shutter doors, the door opening size is 1200*2400, the door frame is made of 304 stainless steel, PVC soft curtain; optional colors: (dark blue, light blue, gray, orange, yellow);

5. Equipped with a transfer window, 800x670x740 outside and 600x600x600 inside, with a cold plate painted outside and a 304 sanded plate inside;

6. Equipped with a corner air shower room, 1200x1200x2180 outside and 880x880x1930 inside, with a cold plate painted outside and a 304 sanded plate inside

7. Equipped with stainless steel lifting adjustable foot cups

8. Top-mounted T5 LED lights: 12 lamps

20W

9. 1 electric control box with F6 control panel

10. Top equipped with ceiling devices (several)

11. All brackets of this clean room do not require on-site welding, and are screwed and fixed on-site;