PRODUCT

Explosion-proof air shower room for chemical plant cleanroom

Explosion-proof air showers are used before personnel enter and exit explosion-proof clean areas, such as:

• Chemical plants (organic solvent workshops)

• Pharmaceutical plants (using flammable solvents such as ethanol and ether)

• Paint and coating workshops

• Workshops with high dust explosion risks (such as aluminum powder, flour, and sugar powder factories)

Explosion-proof air shower room for chemical plant cleanroom

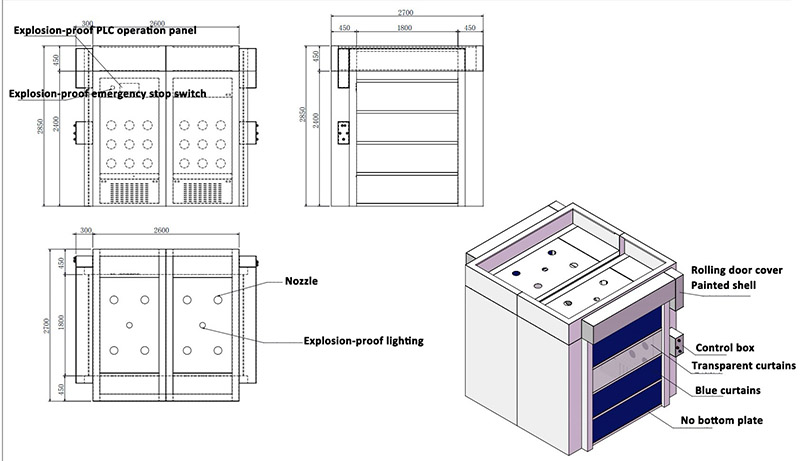

Production specification description

1. Purification level: class100 (air outlet)

2. Dust filtration efficiency 99.99%. Dust particle number/m≥0.3wm.

3. Wind speed: about 25 m/s in strong wind

4. Material: The main plate of the inner box body is made of SUS304 1.2T brushed plate, which is bent and welded.

The main plate of the outer box body is made of SPCC 1.2T cold-rolled plate, which is bent, welded and painted

5. G4 grade primary air filter * 4 pieces

6. Nozzle: stainless steel material, nozzle * 41.

7. HEPA: high-efficiency dry filter * 4 pieces.

8. Control system: PLC control is adopted, equipped with a set of explosion-proof control screen. Automatic blowing, intelligent voice prompt.

With lighting delay, fault alarm prompt, and screen lock function. The initial blowing time is 10S.

9. Door: Explosion-proof PVC rolling door

10. Fan: 4 explosion-proof turbine fans for air shower room. Power supply: 380V. 1.1KW/unit.

11. Explosion-proof grade of accessories: EXd IIB T4

12. The internal cover of the air shower room can be moved to facilitate electrical maintenance and replacement of accessories.

13 Power supply: 380V50HZ 6.5KW three-phase five-wire system.

14. All rough edges are polished and burrs are removed.

15. The finished product is cleaned according to the clean room cleaning standard and covered with a protective film.

16. To comply with the environmental protection policy, the surface is specially polished by precision grinding, not chemical

electrolytic polishing (etching), so as to avoid environmental pollution.

Explosion-proof air showers are used before personnel enter and exit explosion-proof clean areas, such as:

• Chemical plants (organic solvent workshops)

• Pharmaceutical plants (using flammable solvents such as ethanol and ether)

• Paint and coating workshops

• Workshops with high dust explosion risks (such as aluminum powder, flour, and sugar powder factories)

Design features:

• Use explosion-proof motors, explosion-proof fans, explosion-proof lighting, and explosion-proof electronic control systems

• All electronic control components are sealed to prevent arc ignition

• The control box is located in a safe area or uses a flameproof box

• There is grounding protection to prevent static electricity accumulation