PRODUCT

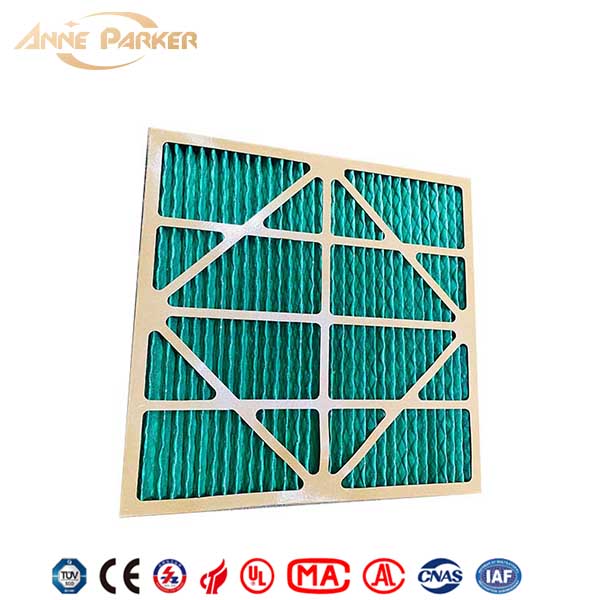

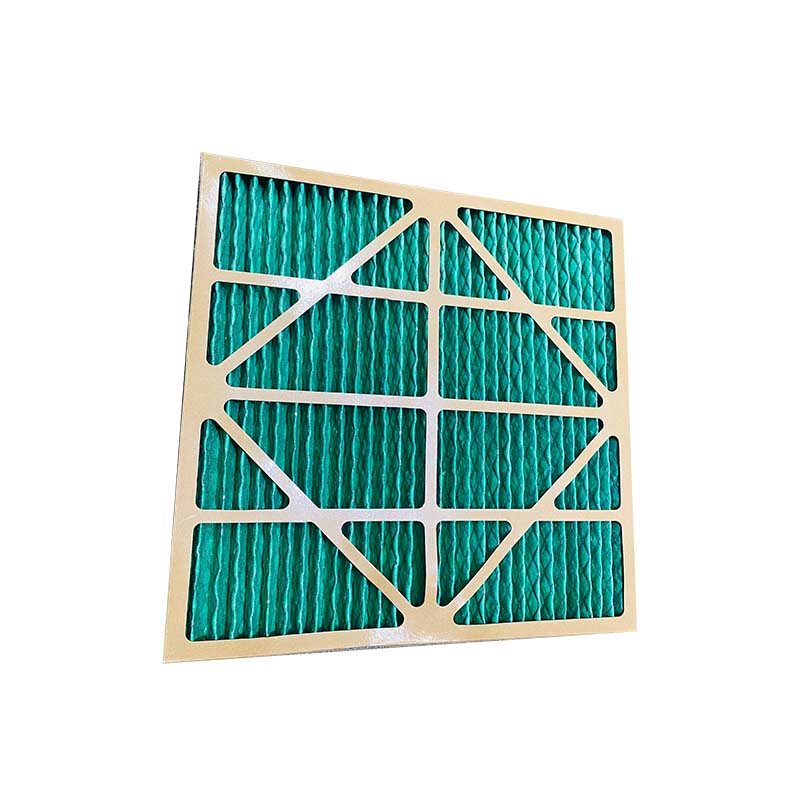

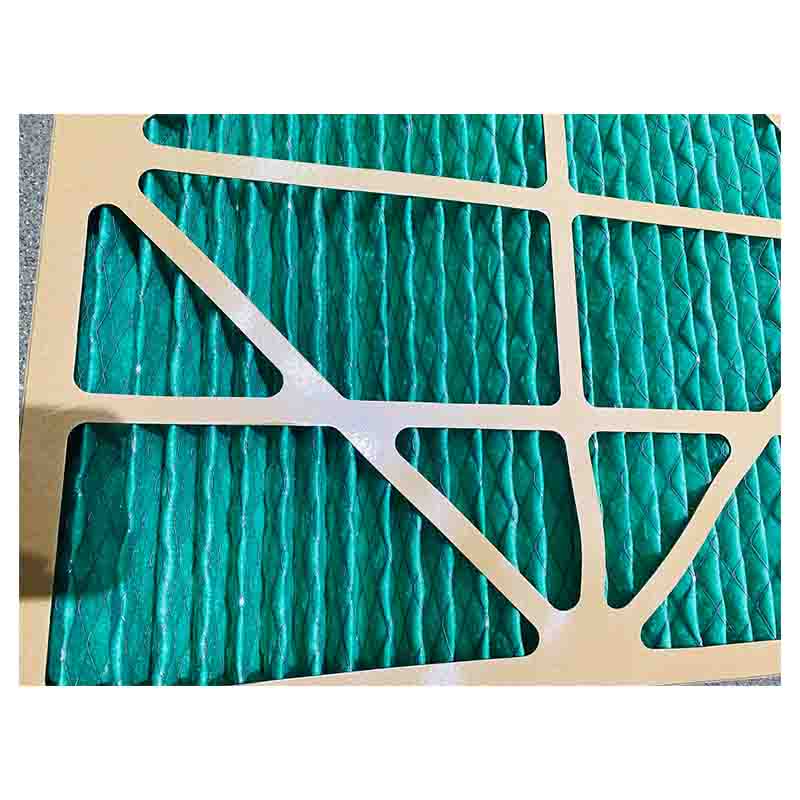

All of our Standard Commercial and Industrial Pleated air filters use the optimum blend of synthetic fibers to insure high dust holding capacity and filtering efficiency. The media is thermally glued to metal backing to prevent the media from sagging during the filter's use. The pleats are formed in a radial configuration to insure proper dust loading.

Panel Filter for Coarse Filtration,Primary filter

Feature:

- Self-supporting material

- No metal, thus fully incinerable

- Low pressure drop media

Technical data:

- G3~G4 EN779; MERV5~8 ASHRAE

- Available in 23mm, 44 and 95mm depth

- Average arrestance: 92%(ASHRAE 52.2-1992)

- DIN 53438 Flammability: F1

- UL 900 Standard: Class 2

- Max air flow rate: 125% of nominal air flow

- Final pressure drop: 2-3 times initial pressure drop

- Thermal Stability: Up to 70ºC

- Moisture resistance: 100% RH

Advantages:

1.The filtration material is made from non-woven fabrics, and the synthetic fiber. It has the advantage of the large dust holding capacity, the low pressure loss in the initial period and lager air flow.

2.The filtration material compounds with the material net, and is designed into the foldaway, which will provide the current air with the largest filtration area, 5 times’ filtration area as the common plane mesh. Paper frame and metal frame are available, which is convenient for replace, less purchasing expense.

3.The moisture-proof: 100%;

4.Heat resistance: 80℃;

5.The rank of the filtration: G4.F5.F6.F7.F8.

Application:

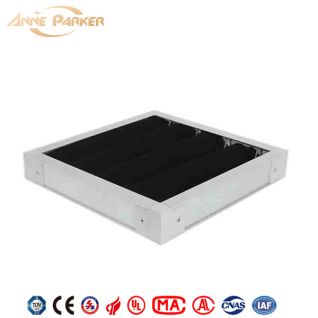

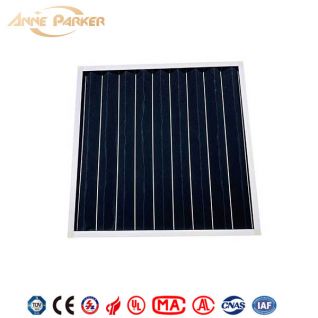

Type: Fiberglass panel filter

Frame: Aluminum, paper or galvanized

EN779 class: G2, G3

Average arrestance: 80%-90%(ASHRAE52.1-1992)

DIN53438 Non-flammability Standard: F1

Final resistance: (suggested) 200Pa-250Pa

Max. air flow: 125% of the rated air flow

Temp. resistance: 100°C

Humidity: 100%

The pleated cartridge is encapsulated in a heavy duty die cut beverage board frame to insure filter integrity in high moisture applications. The pleated filter cartridge is glued to the peripheral interior of the outer frame with a vinyl adhesive, preventing air by-pass. The face of the die cut is internally glued to the apexes of the pleats to insure maximum endurance under adverse conditions.