PRODUCT

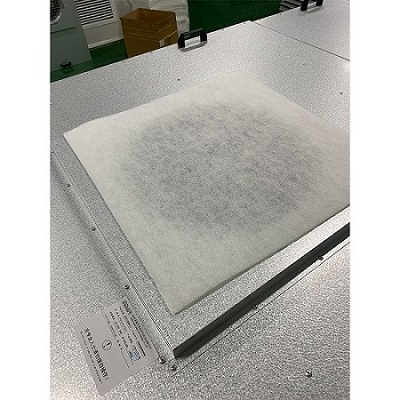

AC /EC Motor Fan Filter Unit ISO 5 cleanroom

1. Rustproof aluminium/Self-contain stainless steel / galvalnium / powder coated steel FFU is compact in size and can be easily installed in Clean Room ceiling grids.

2. Low energy consumption reduces operating cost

3. Our FFU Fan and Filter Unit comes with powerful blowers, which is extre-mely reliable and quiet even under high static pressure.

4. Our FFU are capable of achieving Class 10,000 through

Class 1 Clean Room condition.

5. Control for our FFUs(Fan and Filter Units) can be: 3 speed on device control, 3 speed remote control (with status indicator), computer control,and main-sub controller system.

The MAU + FFU + DC system is a combined Make-up Air Unit + Fan Filter Unit + Dry coil system, mostly used in electronics factories

Fan Filter Unit ISO 5 cleanroom

The FFU group control system can centrally control and monitor a large number of FFUs.

Control FFU operation, stop, speed, and monitor FFU status and faults.

• The control terminal comes in various forms, such as computers, touch screens, LCD screens, etc.

•Support three levels of password protection, and distinguish the authority of different operators.

• It can provide an on-site layout view to display the FFU location and status for easy identification visually. (LCD screen does not support).

• You can set timed tasks to automatically control the FFU at the specified time (only computer support).

•You can record system logs, and you can view historical operations, equipment failures, and other information (only supported by computers).

• Fast communication response speed, the status of 3000 FFUs can be inquiredabout every minute, and the inquiry speed can be doubled by adding a communication interface.

• AC FFU and DC FFU can be mixed in one system, and the group control system provides a unified control interface.

• It can provide dual control functions. When using a computer as the main control terminal, the touch screen or LCD screen can be installed on site as a slave control terminal, and the computer and the slave control. All control terminals can monitor and control the FFU.

• The control terminal can be connected with third-party systems such as firefighting and automatic control for data exchange, or control the FFU according to external input signals.

• Sensors such as wind speed and pressure difference can be added to the system, and the data can be displayed and monitored on the control terminal.

• Customized functions can be added according to customer needs.

|

Model |

FFU0612G-AIU-S-14-I |

|

Dimensions (L×W×H) mm |

1175×575× (225+25) (without filter) |

|

Keel installation size |

1200*600mm |

|

Shell material |

0.8mm galvanized sheet |

|

Fan rated air volume |

1000m3/h |

|

Full pressure |

150Pa(1.5m below the FFU) |

|

Single noise |

≤54dB(A),(@0.45m/s wind speed, 1.5m below the FFU) |

|

Maximum power |

≤135W≤150W |

|

Fan Type/Brand |

Outer Rotor Centrifugal Fan/Avro |

|

Motor type |

Centrifugal fan (domestic brand) |

|

Insulation class |

Class B |

|

Protection class |

IP20 |

|

Filter size and material |

1170*570*70mm, glass fiber |

|

Filter connection |

self-weight seal |

|

Filtration efficiency |

99.995%(@0.3μm ) |

|

Initial resistance |

≤120Pa (0.45m/s) |

|

HEPA face mesh |

Stencil surface spray mesh |

|

HEPA seal |

EVA |

|

Way to control |

DC group control step-less speed regulation |

|

Power supply |

AC single phase 220V 50Hz |

|

Group control function |

1. Monitor the running status of FFU in real-time. 2. There is a historical record of the running status of the FFU, which can be set to work mode, night mode, holiday mode, automatic switch, and can control the switch of the FFU regularly. 3. The system can realize the control of starting, stopping, adjusting the motor speed, and adjusting the air volume of the FFU (single control and group control); real-time monitoring of the running status, speed value, and alarm display of the FFU. |