PRODUCT

Product Description

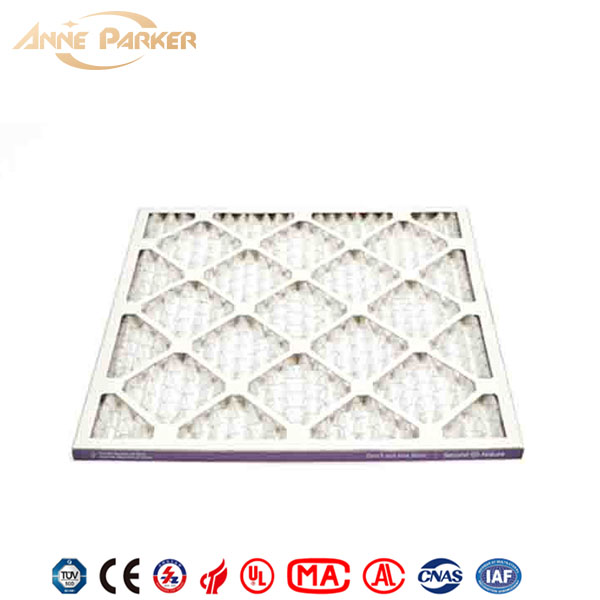

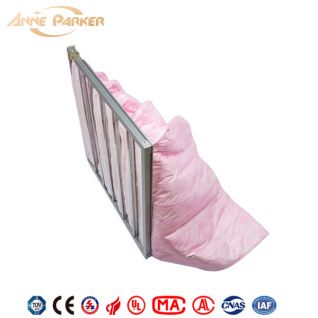

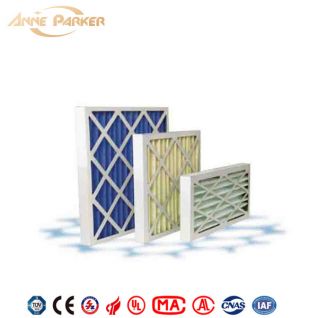

The primary filter (also known as pre-filter or coarse filter), English name is Primary Filter or Pre-Filter.

It is mainly used in the primary filter section of the clean room to filter dust particles above 5μm, and is widely used in optical electronics. , medical and pharmaceutical, food and beverage, biological experiments and other industries.

1. The filtration material is made from non-woven fabrics and synthetic fiber.

It has the advantage of a large dust holding capacity, a low pressure loss in the initial period, and larger air flow.

2. The filtration material compounds with the material net, and is designed into the foldaway, which will provide the current air with the largest filtration area.

5 times the filtration area of the common plane mesh. Paper frames and metal frames are available, which is convenient for replacement, with less purchasing expense.

3. The moisture-proof: 100%;

4. Heat resistance: 80℃;

5. The rank of the filtration: G4.F5.F6.F7.F8.

Product Description

1. Large dust holding capacity

2. The low pressure loss in the initial period

3. Large air flow

Advantages:

• Excellent prefilter for higher efficiency filters

• Excellent primary filter to prevent dust build-up on heating

• an cooling coils, fans, and ductwork

• High-loft synthetic media

• Four Efficiencies range from MERV 6, MERV 7, MERV 9

• 1", 2", and 4" models

• Premium performance and construction

• For simple storage, installation, handling, and removal

• Each filter includes a label noting tested efficiency, pressure

drop ,rated airflow

It is generally used in conjunction with other air purification equipment, such as FFU, air shower, clean shed, etc. The outer frame material of the primary filter can be selected from stainless steel, paper frame, aluminum Frame, galvanized frame, etc. Filter materials include non-woven fabric, nylon mesh, activated carbon filter material, metal mesh, etc.

Prodction Process

Delivery

Delivery

Payment

Payment