PRODUCT

HEPA Filter FFU EBM EC Motor cleanroom fan filter unit

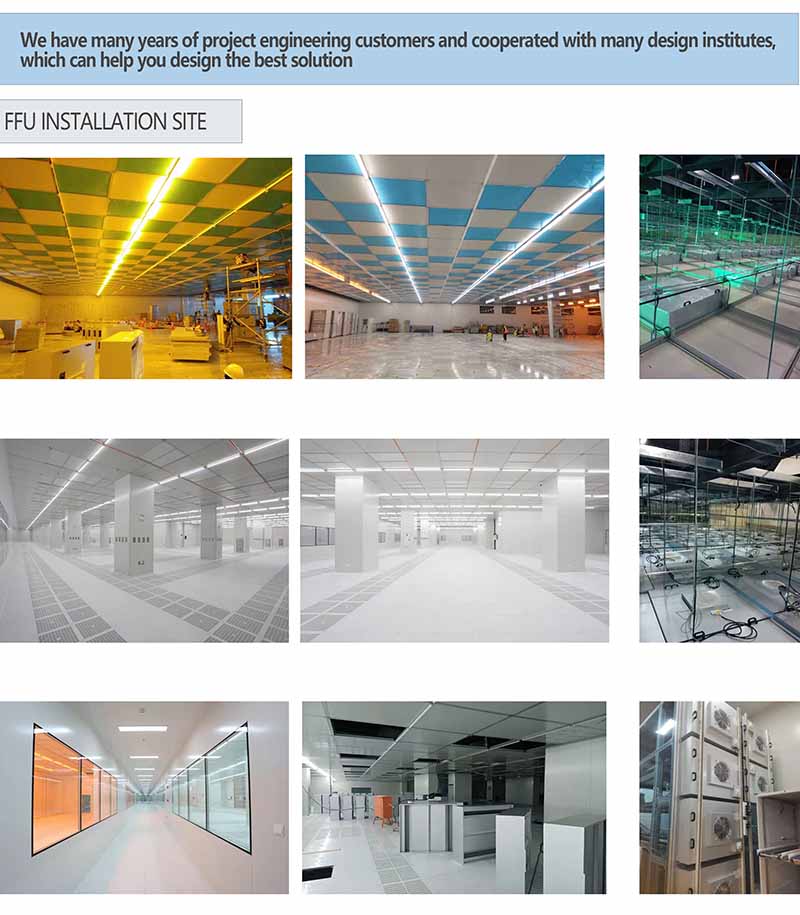

1. Our Fan Filter Unit FFU system is very versatile and flexible, capable of

supporting any Clean Room configuration, layout and

level of cleanliness. It can also be used in many other

applications, such as clean booths, clean workbenches,

and Clean Room tunnels.

2. Rustproof aluminium/Self-contain stainless steel / galval

-nium / powder coated steel FF is compact in size and

can be easily installed in Clean Room ceiling grids.

3. Low energy consumption reduces operating cost

4. Our FFU Fan Filter Unit comes with powerful blowers, which is extre-

mely reliable and quiet even under high static pressure.

5. Our FF are capable of achieving Class 10,000 through

Class 1 Clean Room condition.

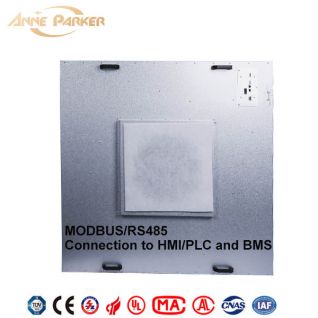

6. Control for our FFUs(Fan Filter Units) can be: 3 speed on device control,

3 speed remote control (with status indicator), computer

control,and main-sub controller system.

|

FFU Motors and Brand |

EBM EC Aluminum Impeller FFU |

EBM DC Plastic Impeller FFU |

Gebhardt EC Metal Impeller FFU |

|||

|

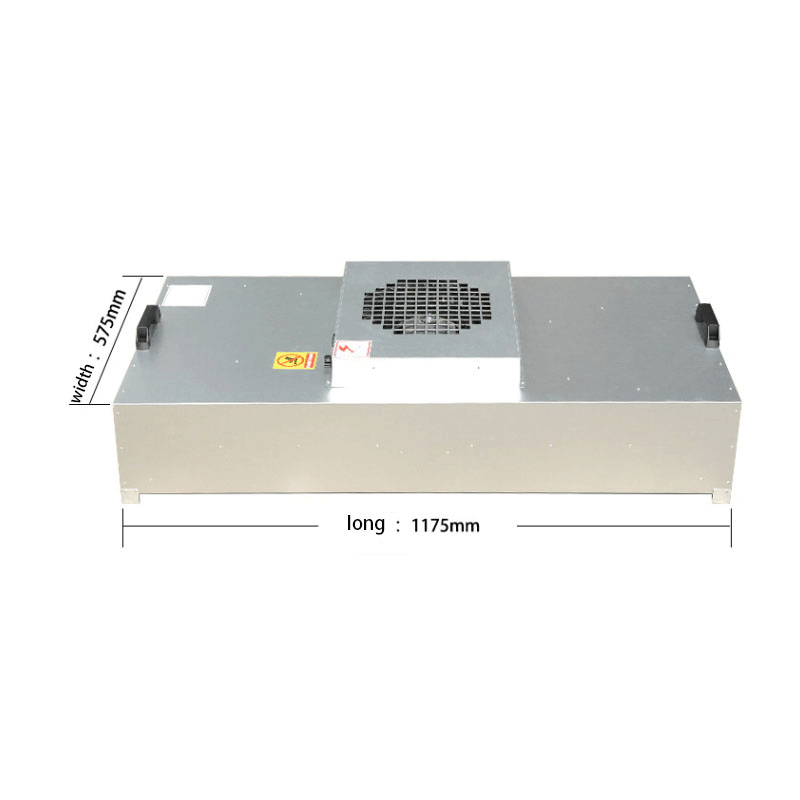

FFU Size(mm) |

1175*1175*(320+25) |

1175*575*(320+25) |

1175*1175*(320+25) |

1175*575*(320+25) |

1175*1175*(290+30) |

1175*575*(290+30) |

|

Box Material |

Galvanized sheet, Stainless steel, Aluminum sheet |

|||||

|

Rated air volume (m³/h) |

2000 |

1000 |

2000 |

1000 |

2000 |

1000 |

|

Static pressure (Pa) @0.45m/s |

320 |

380 |

280 |

300 |

360 |

360 |

|

Noise dB(A)@0.45m/s |

55 |

51 |

52 |

49 |

50 |

48 |

|

Maximum Power (W) |

≤350 |

≤350 |

≤310 |

≤310 |

≤400 |

≤400 |

|

Running Power(W) @0.45m/s |

145 |

85 |

135 |

75 |

120 |

70 |

|

Overall Efficiency |

55% |

|

58% |

|

60% |

|

|

Machine type |

DC Brushless motor |

|||||

|

Insulation class |

B |

|||||

|

Protection class |

IP20 |

|||||

|

Fan type |

Lean back |

|||||

|

Bearing maintenance free time |

100,000 hours |

|||||

|

Impeller material |

Aluminum Impeller |

Plastic Impeller |

Aluminum Impeller |

|||

|

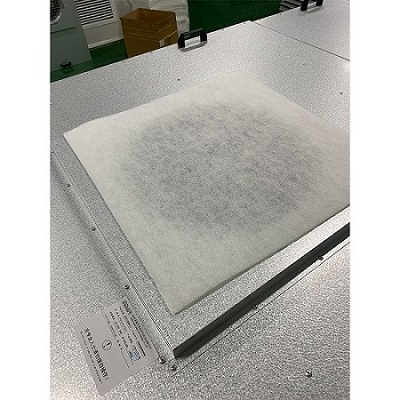

Filter size(mm) |

1170*1170*70 |

1170*570*70 |

1170*1170*70 |

1170*570*70 |

1170*1170*70 |

1170*570*70 |

|

Filter material |

Glass fiber, PTFE |

|||||

FFU CONTROL SYSTEM

• The FFU Fan Filter Unit with hepa filter group control system can centrally control and monitor a large number of FFUs.

Control FFU operation, stop, speed, and monitor FFU status and faults.

• The control terminal has a variety of forms such as computers, touch screens, LCD screens, etc. to choose from.

•Support three levels of password protection, and distinguish the authority of different operators.

• It can provide an on-site layout view to visually display the FFU location and status for easy identification. (LCD screen does not support).

• You can set timed tasks to automatically control the FFU at the specified time (only computer support).

Note:

1. H is a high static pressure type, S is a standard type;

2. FFUs of the above specifications are not equipped with phase-effect filters, if you need to be equipped with coarse-efficiency filters,

you need to add an

explanation when ordering, and the height of the FFU is also Will increase by 30mm accordingly.

3 Standard operating conditions refer to the operating conditions when the rated wind speed is 0.45m/s and the residual

pressure outside the machine is 50Pa (120Pa).

4. The maximum power consumption is the power consumption when the FFU air volume is at its maximum.