PRODUCT

Mist Air Shower Spray air shower room supplier

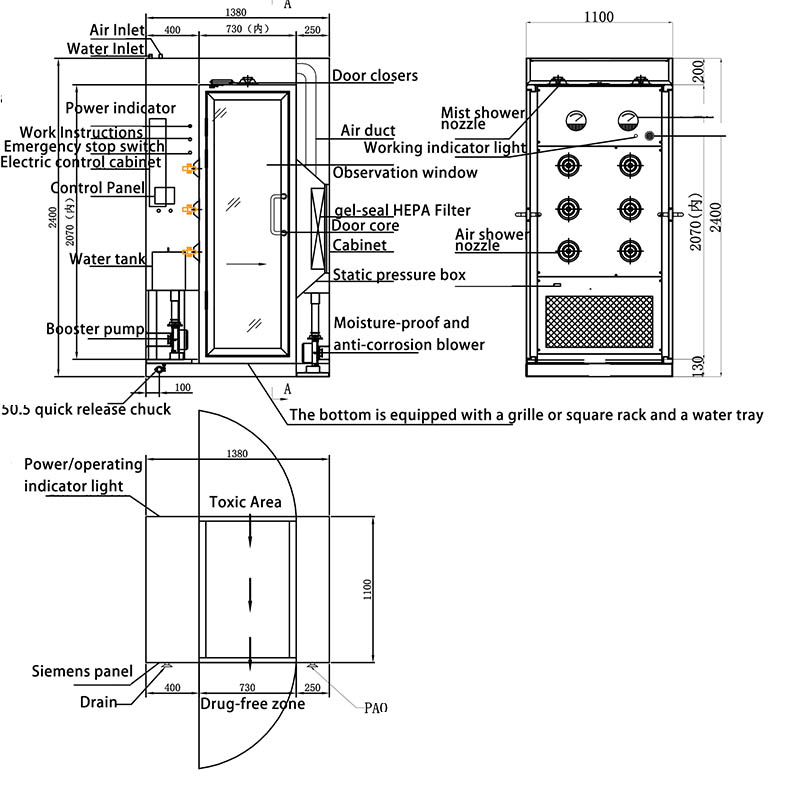

Specifications: W1380XD1100×H2400mm (outside)

W 730XD 960×H2070mm (inside)

1. Box and inner wall material:

a. The box and outer bottom frame are made of 304 sanded stainless steel plate, with natural sanding on the surface;

b. The inner wall is made of 304 sanded stainless steel plate, with natural sanding on the surface:

c. The inner bottom plate is made of 304 sanded stainless steel plate, with natural sanding on the surface:

Product name: Mist shower in the pharma Spray shower room

Specifications: W1380XD1100×H2400mm (outside)

W 730XD 960×H2070mm (inside)

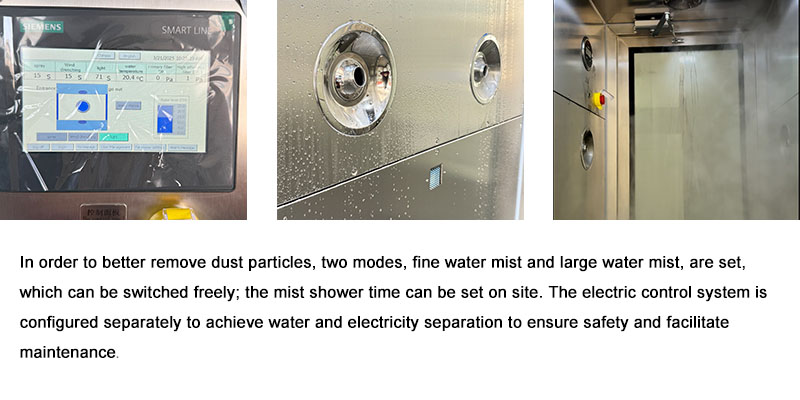

Liquid spraying and air spraying functions can be realized automatically and manually through PLC.

The button touch screen can be placed simultaneously

to control liquid spraying and air spraying simultaneously, or only air spraying without liquid spraying.

Configuration and technical parameters:

1. Box and inner wall material:

a. The box and outer bottom frame are made of 304 sanded stainless steel plate, with natural sanding on the surface;

b. The inner wall is made of 304 sanded stainless steel plate, with natural sanding on the surface:

c. The inner bottom plate is made of 304 sanded stainless steel plate, with natural sanding on the surface:

2. Double door electronic interlock (electric lock, door magnet, relay constitute the interlocking system):

3. Door material:

a. The door frame is made of 304 sanded stainless steel plate:

c. The middle window of the door is made of hollow tempered glass:

4. Equipped with Siemens 7-inch control panel + PLC control system (the control panel is only installed in the direction of exit):

5. Equipped with 2 sets of Dryer pressure differential gauges to detect high-efficiency and primary pressure differentials respectively:

6. Equipped with a water tank and a booster pump:

7. Door opening direction: B direction

8. Power supply: 3P/AC380V/50Hz/3.OKW.

9. Equipped with a set of PAO detection and injection ports for detecting gel seal HEPA filter

Mist shower in pharma Equipment parameters:

1. Equipment power: 380V 50Hz 3.0 KW

2. Water inlet pipe: G1/2 external thread - water supply (purified water)

3. Air pipe: ¢8 quick connector - compressed air: 6KG

4. Drain: ¢50.5 chuck

5. Water supply, electricity, and gas are all from the top of the equipment

Product functions:

1. Used to clean dust/spray disinfection on workers;

2. Emergency stop switch is set in the spray area, and there is no control panel:

3. The door closer device ensures that the door cannot be opened automatically when not in operation;

4. The bottom of the equipment is made of a stainless steel grille or square frame, and the bottom is equipped with a water guide plate;

5. The door glass window can be used to check the situation in the work area at any time, which is convenient for use;

Working principle:

The worker enters the mist shower room: first open the front door, enter the mist shower room, and close the door. When the photoelectric sensor

is touched, the light turns on and the spray stage begins. The spray section starts working. After working for a period of time (0-30 minutes adjustable),

the spray stops;

The air shower stage begins, the blowing section starts working, and after working for a period of time (0-30 minutes adjustable), the fan stops

working, and the back door can be opened to go out; the blowing only blows air, without a heating function. One-way operation:

2. Spray stage, induction control, adjustable working time;

Blowing stage, after the mist shower ends, the blowing starts, and the spraying time is adjustable: