PRODUCT

Static Pass through box for pharma cleanroom Electronic interlocking SUS304 with UV lamb

Basic performance requirements

●The inner and outer double-layer shells are rounded on all sides to ensure seamless connection.

● Internal control function: UV lamp, designed with a separate switch

● Double door interlocking effectively prevents cross-infection.

● Can be equipped with a paging intercom

● High sealing performance

Static Pass through box for pharma cleanroom Electronic interlocking SUS304 with UV lamb

1. Overview

The transfer window is the most effective device to prevent pollution. It features double-door interlocking. It is mainly used

for the transfer of small objects between clean rooms and non-clean areas or between clean rooms of different levels and

pressures. It effectively reduces the number of times staff members need to transport items to the clean room and prevents

external air from polluting the clean room. This equipment is widely used in the pharmaceutical industry, biological laboratories,

electronics industry, food processing industry, and other places that require air purification.

2. Installation

The transfer window is installed on the partition wall between the clean room and the non-clean room.

The installation environment: temperature is 15℃---35℃, humidity is 40%RH---70%RH.

3. Technical parameters

| Model | Mechanical interlocking pass box | Electronic interlocking pass box | Magnetic interlocking pass box |

| Supply voltage | None (with UV lamp 220V/50Hz) | 220V/50Hz | 220V/50Hz |

| Box material | Cold rolled plate/stainless steel plate | Cold rolled plate/stainless steel plate | Cold rolled plate/stainless steel plate |

| Inner wall material | stainless steel plate | stainless steel plate | stainless steel plate |

|

Model |

Mechanical interlock

|

Work area size |

Power (Kw) |

|

AN-400 |

600*700*450 |

400*400*400 |

0.1 |

|

AN-500 |

700*570*550 |

500*500*500 |

|

|

AN-600 |

800*670*650 |

600*600*600 |

|

|

AN-800 |

1000*870*850 |

800*800*800 |

4. UV sterilization

Primary Germicidal Wavelength: UVC (short-wave ultraviolet, 200-280nm)

Mechanism of Action: UVC photons have extremely high energy and can directly penetrate the cell membranes of

microorganisms (bacteria, viruses, fungi, etc.), binding to thymine (T) in DNA/RNA, forcing the formation

of "thymine dimers (T-T)"—this abnormal structure leads to DNA strand breaks and replication errors, preventing

microorganisms from dividing and reproducing, ultimately leading to "inactivation" (equivalent to "sterilization" or direct death).

Germicidal Efficiency: The killing rate of common pathogenic bacteria (such as E. coli, Staphylococcus aureus),

viruses (such as influenza virus, COVID-19 virus), and fungal spores can reach over 99%,

making it the core working wavelength of ultraviolet sterilization lamps.

Auxiliary Wavelength: UVB (medium-wave ultraviolet, 280-320nm)

Mechanism of Action: Lower energy than UVC, it primarily inhibits microbial metabolism indirectly

by damaging the protein structure of microorganisms (such as the active sites of enzymes).

Its germicidal efficiency is far lower than UVC and is usually used as an auxiliary

or supplementary method in specific scenarios (such as surface disinfection of water).

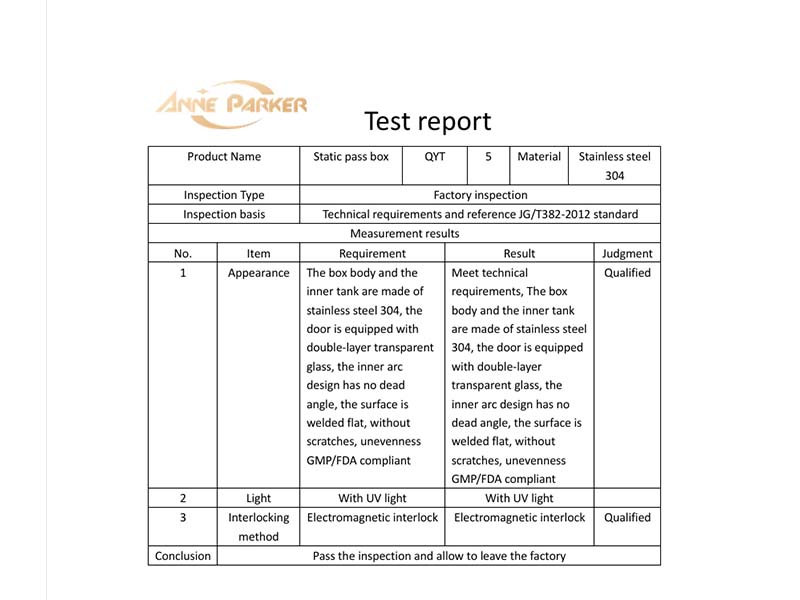

All products will be equipped with test reports before leaving the factory.